Proventia Batteries: Developing Energy and Power Batteries for Machine Electrification

Discover how Proventia’s battery packs are advancing the electrification of non-road machines and other equipment with similar needs.

Discover how Proventia’s battery packs are advancing the electrification of non-road machines and other equipment with similar needs.

Proventia proudly introduces its new European LFP technology-based battery packs at Bauma. The benefits of this new product are remarkable, from exceptional engineering to high-quality European origins. Also the reliable LTO technology continues to perform strongly when a robust working cycle or peak power is needed. Learn more about Proventia’s offerings below!

Proventia wants to ensure that the client will succeed in their electrifying project and chooses the right type of battery technology.

LTO (lithium titanate oxide) is the answer when the battery is subjected to intense use that other chemistries can’t handle. This includes fast cycling and high-power intensity. LTO is the right choice also when there’s low temperatures involved or the application is safety critical and basically other technologies are not allowed.

LFP (lithium iron phosphate) technology is also a good option for heavy machinery, for its cost-efficiency with a long lifespan. The high-energy, high-voltage battery systems are suitable for continuous operation over extended periods.

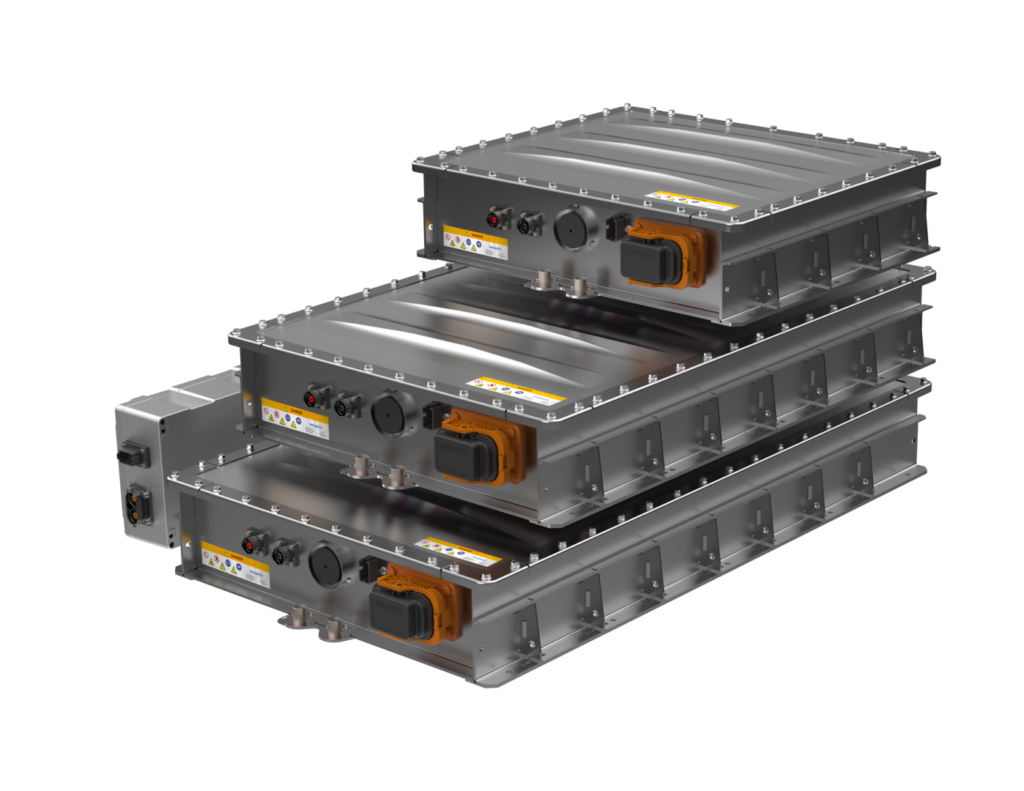

The new Proventia Energy is a robust, safe LFP battery pack with a long cycle life and high thermal stability. The chemistry inside the battery pack delivers consistent energy and is highly compatible with applications such as heavy work machines, wheel loaders, tractors, and more, either in full electric applications or as a zero-emission energy source in a hybrid system. Proventia Energy supports more cycles (over 6,500 charges) and operates across a wider temperature range (-20°C to +55°C), and it can utilize the full capacity of the battery.

LFP technology is also more environmentally friendly because it doesn’t contain harmful substances like nickel, cobalt, or manganese. The main materials are widely and easily available, and its lifespan is longer than that of competing energy chemistries.

The physical size of standard Proventia Energy battery packs is set to a standard width of 750 mm. The design focus of the Proventia Energy battery is on the efficient use of space to achieve high energy density. The number refers to the amount of energy stored within a given volume or mass. The design target for an LFP battery pack is as high as 145 watt-hours per liter.

Last but definitely not least, Proventia Energy battery packs are designed and manufactured using battery cells from the Norwegian cell producer MORROW Batteries, making Proventia Energy one of the first fully European-origin products in the LFP sector.

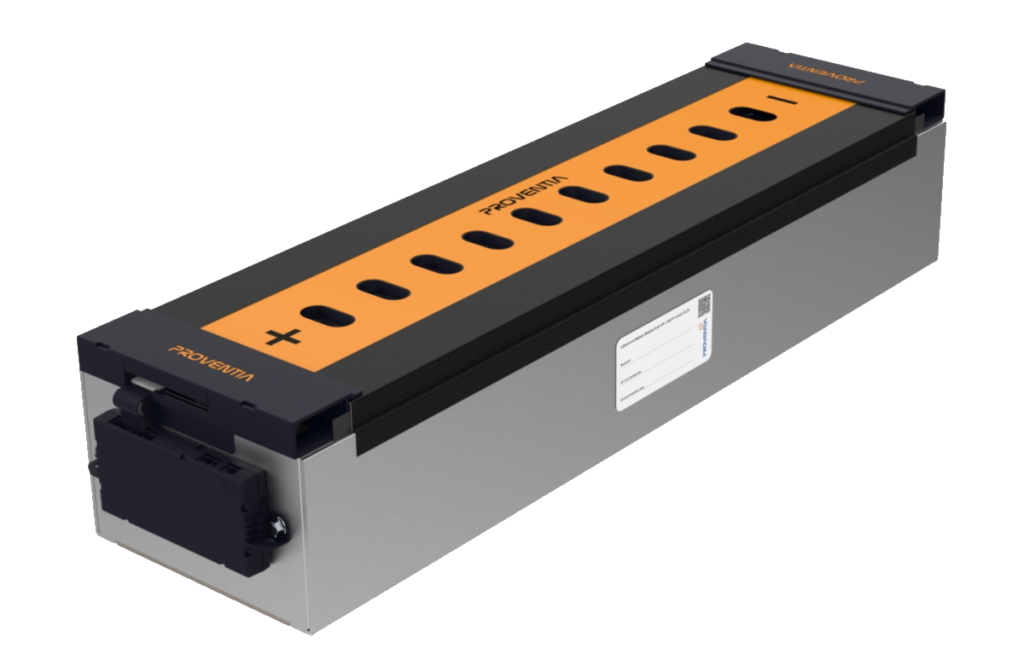

The 30 years of Proventia’s history gives a great background of understanding the heavy work and mechanical stress. LTO technology based Proventia Power batteries are truly designed for harsh use, in which the battery gives that extra power for lifting, crushing, cutting, and so on.

LTO is the safest of all battery chemistries and the strongest for specific hybrid applications, where the constant energy source comes from a combustion engine or fuel cell. Thanks to its rapid charging ability, it is also suitable for full-electric applications, especially when there is infrastructure to support regular charging — not just fortnightly, but during working hours. While LTO batteries have slightly less capacity, the capacity they do have can deliver rapid peak power.

LTO batteries hold the record for the longest cycle life, as well as the highest charging and discharging power. Proventia Power batteries feature extremely high C-rates, ranging from 10 to 40 C, meaning they charge very quickly. Proventia Power batteries also have the widest operational temperature range, allowing them to be charged in sub-zero temperatures.

Proventia batteries are developed, designed, simulated and tested at the Oulunsalo Technology Center in Oulu, Finland. The battery team consists of engineers with decades of experience in developing cleaner power solutions.

Typically, batteries are built with aluminum covers, but Proventia’s are made of stainless steel. They are paint-free, resistant to rust, and inherently robust. Stainless steel also has a smaller carbon footprint. Additionally, an integrated battery cooling system is built into the battery’s framework, eliminating the possibility of liquid leaks.

The European Commission has set regulations to ensure that batteries placed on the EU market are sustainable and circular throughout their entire life cycle. Proventia is fully prepared for European battery regulations.

The battery development project begins by defining the required performance that the battery should be able to deliver. After determining key parameters, including voltage, capacity and power, simulations are used to ensure that the battery will work properly in the specified application and the working cycle. Prototype production and field tests follow. The goal is to validate functionality before production begins.

Both of Proventia’s batteries, Energy and Power, are based on a modular standard family. The suitable solution is first observed whether it can be created by assembling standard products. If this isn’t possible, the solution will be customized, while still using Proventia’s battery modules to avoid starting from scratch.

If the project meets specific criteria, such as volume and resource allocation for tailored solutions, Proventia is ready to apply its engineering expertise. However, the ultimate aim is to maximize the benefits of volume as much as possible.

Our new LFP Energy Battery will be showcased for the first time at Bauma, the World’s leading construction machinery trade fair, on April 7 to 13, 2025, in Münich, Germany.